|

Power Ratings The power ratings you'll see below are the power dissipation capacity needed for a contemporary CPU of that power output (not TDP, actual power) to run well. CPUs from around 2015 onward would use more power than their TDP rating if it was available, this is factored in. The rating is intended to be a guide to "Will a x watt CPU be thermally limited by this cooler?" For example, a Ryzen 5 5600X is rated to a 65 watt TDP but has an actual maximum power (by default) of 80 watts and will use this in all-core workloads. Therefore, you need to be looking for a cooler capable of 80 watts with that CPU, more if you intend to overclock it. Testing Each heatsink was tested with a power resistor on the base which had a temperature probe (thermocouple) between it and the heatsink base. This thermocouple was embedded in a small etched channel in the power resistor. The results are given in degrees over ambient (DOA), and ambient was usually around 20C. The provided fan, if any, was on full from a 12V supply. This allows heatsinks with meatier fans to force their way up, or coolers which crap fans to fail. The results are directly comparable within the same power rating, but give it around 2-3C either way for accuracy. These aren't scientific tests, they're for indication only. Bad is anything over 60 at the power level you're interested in. Heatsinks weren't usually tested outside the range of the CPUs they'd be used with contemporarily. These results will be lower than real CPUs, since CPUs offset their actual temperature to give a thermal-junction (Tj) value, intended to simulate the top of the integrated heatspreader. This started in roughly the late Core 2 era on Intel, and AMD moved to giving a "Tctl" value, meant as a fan controller, so would not rise as quickly as actual CPU die(s), and not fall as quickly either, to avoid rapid changes in fan noise pitch. Also real CPU dies are very small, usually less than 200 mm², making cooling them more difficult than the large contact area of my power resistor, which has over ten times the area. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Alpha PAL8045 Designed for Socket A exclusively, the Alpha PAL8045 (Dan's reviews are known to give heatsinks a much higher C/W than usual, but he's very consistent. He considers the PAL8045 to be 0.53 C/W) was regarded as the king of all Socket A heatsink coolers, though in its later years upstarts such as the Swiftech MCX 462 and the various all-copper Evercools managed to supplant it - But only with the help of a screamingly loud fan. As far as quiet, efficient heatsinks go, the PAL8045 was not beaten until the heatpiped tower coolers started to appear five years later. The PAL8045 was so efficient that increasing the fan to one with four times the output made very little difference to the effectiveness of the heatsink. Using Alpha's "Microforge" process, the aluminium cooler had, as can be seen, numerous small hexagonal pins instead of the traditional fins or vanes. This gave it a massive surface area and increased its density, both important for a heatsink. This caused a large pressure drop from the top of the heatsink to the bottom which is normally a bad thing. Air couldn't flow as freely through the PAL8045 as it could a traditional cheap fin thing (see the Evercool below for a typical example). This meant the PAL8045 didn't benefit much from very powerful fans, but the trade-off which Alpha hit a perfect sweetspot on was that the PAL8045's surface area was massive. The heatsink didn't have the same kind of airflow as hairdryer emulators but it made much better use of the airflow it did get. The copper inlay was used for its high thermal conductivity, it spread the heat load across the base of the heatsink so that the outer areas were more effective and the heatsink could be made larger than the typical 60mm. In this case, the heatsink was a full 80mm and one of the first of the 80mm heatsinks which used fans which before then had typically been reserved for case cooling. 80mm fans are able to move more air at a lower RPM rate, so be just as effective at a lower noise level. Being a bolt-through-holes cooler, the heatsink required a motherboard compliant with AMD's mounting hole specifications which not all of them were. Common designs from Gigabyte, Asus, Abit and DFI were compliant, I used it with an Abit KT7, KT7A, KX7-333 and Asus A7N8X-X, but cheaper boards typically didn't bother - Check the PC Chips/ECS board in the motherboards section, the two mounting holes comply with no known specification. It cost a fortune, it wouldn't fit all motherboards, it required assembly, it usually didn't come with a fan, but if you could fit it, use it and set it right...oh boy were you in for a treat. Typically the PAL8045 would be comfortable with a thermal power of 60-80 watts, placing it well at the top of what heatsinks of its time were both capable of and expected to do. Type: Extruded pin, copper inlay Fan size: 80 mm Power rating: 65-80 watts

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Evercool CUD-725 There are two ways of making a heatsink. You can do the smart way, design a precision made instrument (see the Alpha above) and charge a fortune for it but sit back and know you're putting the newbies in their place. Or you can put together a few fins and a screamingly powerful fan on top (Anyone ever seen an OCZ Dominator? No? Bet you heard it coming, though!) of an otherwise unimpressive heatsink and be guaranteed great performance. Sure, you wouldn't beat the Alphas of the world, but you'd be about half their price. With a screamingly loud Delta 70mm fan and an all-copper design, the Evercool CUD-725 belongs in the latter category. It's actually heavier than the Alpha PAL8045 (though not by much) but a lot cheaper to make. It's a skived-fin copper thing completely lacking in grace and subtlety. That's not to say it was bad, far from it, but that it wasn't excellent. It performed within a hair of the Alpha PAL8045, but at a much higher noise level. A simple design, done well, the rulebook followed to the letter. Most testing placed the CUD-725 around the 0.60 C/W level. This would make the cooler suitable for the highest Socket-A workloads, 80 watts or more. The unusual 70 mm fan was difficult to replace. Type: Low density copper fin array Fan size: 70 mm Power rating: 65-80 watts

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Akasa AK-??? This style of cooler was quite common in the mid-2000s. It's your basic skived aluminium fins with a copper plate on the bottom. A screwed on fan bracket took a 60 mm fan. They weren't awful. The copper base did exactly what it was intended to and got heat out to the edges better than aluminium could by itself. This was a similar design to the earlier AK-795 Socket A cooler (which used a huge copper block as its base!) and in my notes here I have it down as a Socket AM2 cooler, but it may have been a Socket 939 cooler (Those two sockets used interchangeable heatsinks). It was not Akasa's budget line, which didn't use fan brackets but directly attached fans, and tended to use only one mounting lug. It has so far resisted all attempts to positively identify it. The AK-795's fin profile is slightly different, but the mounting clip and fan retention are identical, so this is clearly a socket update to the AK-795, for Socket 939 or AM2. At the time, I believe this was in use on an AMD Athlon X2 5200+ which was hosting the hattix.co.uk server of the early to mid 2010s, though my only pictures from that system running show it with the AMD stock cooler. Type: Low density aluminium fin array with copper base Fan size: 60 mm Power rating: 60-75 watts

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Heatpipes |

The one thing which revolutionised cooling more than anything else was the heatpipe. Everyone knows what a heatpipe is, it's a low pressure copper tube with a sintered inside and a small amount of working fluid in it, usually water, sometimes other fluids. The low pressure allows the water to evaporate easily on the hot side and it condenses on the cold side. Water's very high heat of vapourisation then efficiently transports the heat energy from the hot to the cold side. They can work in any orientation, so long as they're still at low pressure (aged heatpipes can have air leaked in, which then means we need to have the hot end lower than the cool end). Heatpipes have a thermal conductivity hugely higher than solid copper does. We measure it using the heat pipe's "effective length" which is the distance from the middle of the fin stack to the middle of the mounting block, along the heatpipe. For a common 7 mm diameter, 150 mm heatpipe with an effective length of around 100 mm, around the ballpark for most CPU tower coolers, the effective thermal conductivity is around 30,000 W/m-K (this depends on conditions, it is lower when hotter). A copper rod of similar dimensions will measure in at around 385 W/m-K. No solid material comes even close to challenging heatpipes. The most thermally conductive metal, silver, has a thermal conductivity of about 410 W/m-K in the same conditions. Gold is also highly rated, at 310 W/m-K, and so is aluminium, at 240 W/m-k. Nearly all other metals (except magnesium and zinc), are less than 100 W/m-K and usually much lower. Normal structural steel is around 20 W/m-K and copper alloys, like bronze, are also much lower than copper itself, bronze is merely 28 W/m-K and yellow brass is much worse than both its constituents (70% Cu, 30% Zn) at 110 W/m-K. The platinum group isn't great, around 60-80 W/m-K. Even the finest thermal conductor, diamond, is around 950-1,100 W/m-K. A heatpipe is two orders of magnitude better than any other material. The point is, heatpipes utterly wipe the floor with anything else. They allow us to make much larger heatsinks and ensure that the most distant part of the heatsink from the heat source is in very good thermal contact with it. This was a huge problem in heatsinks before we had heatpipes, the outer most fins just got no heat, even if the central fins were running extremely hot. Heatsinks work on surface area and conductivity, but if conductivity isn't high enough, surface area also cannot be very high, there just isn't enough room to put all the fins without them being so thin that their thermal conductivity is impacted as a result! The first heatpipe heatsink I can think of, and a predecessor to all towers today, was the Cooler Master CH5-5K12 (nice names, CM) which had two heatpipes and wiped the floor with every other cooler of the day, so much so that it was seen as irrelevantly exhorbitant! All serious heatsinks today use heatpipes. Those that don't tend to be small and of limited effectiveness. Most large tower coolers are not airflow limited, and adding excessive airflow doesn't really benefit them. They're limited by how good their heatpipes are, how many of them there are, and their fin stack surface area. In some very low end cases, they can also be limited by their thermal interface. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Cooler Master Hyper6+ Sat atop an ATX PSU for scale (as are most of the other heatsinks on this page), the Cooler Master Hyper6+ is a six-heatpipe two-stage tower cooler with copper heatpipes and aluminium vanes. In the original Hyper6, the vanes were also copper which added a great deal to the mass of this behemoth, but the aluminium version weighs in at 'only' 971g. In use, the Hyper6+ was able to keep an estimated 110W load (2.8GHz dual core Opteron at 1.45V) at 65C with the fan turned down to only 80% PWM - From this I work out an excellent real-world thermal resistance of 0.20 - 0.25 C/W. In design, it has a large copper slug on the bottom to make contact and house the hot end of the heatpipes but where most coolers then have a whole load of open space doing nothing, the Hyper6+ fits a first-stage heatsink which cannot harm performance but probably won't make much difference. The aluminium vanes are closely spaced but parallel, well fitted and offer very little resistance to airflow. It's big, effective, imposing, weighs almost a kilogram...and the fan glows blue. What more could one want? Alas, the universal fitting of the Hyper6+ fits all current (and past) sockets with mounting holes...except Socket F and Socket AM2(+). When I moved to AM2, the Hyper6+ had had to be retired... Until, like with most of my hardware, it found use in this server, during the years it was running as an Opteron 165. Quiet, extremely high performing and reliable. Just what you need in an always-on system. It has since been retired as it fits no modern socket. Other than the lack of AM2 compatibility, the other problem with the Hyper6+ is its use of a non-standard 100mm fan. 92mm and 120mm are standard, but 100mm fans are extremely difficult, almost impossible, to find. Type: Six heatpipe tower Fan size: 100 mm Power rating: 80-125 watts

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Zalman VF900-Cu - 2006 This is not like most of the other coolers here. This was a video card cooler, meant to be fitted to a GPU. It uses an all-copper design with radial vanes and two heatpipes from the cold-plate out through the outer edges of the vanes. This is a very clever design! While copper has pretty good thermal conductivity, heatpipes are so much better. This gets the edges of the heatsink as much thermal contact as is possible, so making most use of the copper. The inside of the copper vanes has little contact but, with heatpipes doing the job, it probably doesn't suffer much. I used this with a GeForce 7900GTO, which ran its GPU around 75 watts. While telemetry back then wasn't available, the overclock I had on it probably had it between 80 and 90 watts. The VF-900 was much smaller than the stock cooler, a lot quieter, and usually ran a degree or so warmer, so more or less the same performance. With the heatsink being so much better at getting heat off the GPU, it didn't need as much airflow. While we often say cooling is a surface area race, and it is, this is only really comparable if the material is unchanged. Copper conducts heat better than aluminium does, by a lot, so will conduct it into the air better too. If you touch a copper surface and an aluminium surface of the same temperature, the copper one will feel warmer (if the temperature is above body temperature) or colder (if the temperature is below body temperature) as it will more readily conduct heat into you or away from you. The same holds true for airflow. Copper will "lose heat" faster, though this is really just copper's better conduction. You also get a pack of cool blue anodized memory heatsinks with the cooler. They're nothing special, but they also do not need to be! Type: Radial vane heatpipe Fan size: 80 mm Power rating: 100 watts (Estimated: Zalman did not provide a power rating)

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

No Images Yet |

Akasa Freedom Tower - 2010 The basic four heatpipe tower cooler design (which Cooler Master did so well with the Hyper 212 series) is four bent heatpipes in a U configuration, their middles flattened to directly contact the CPU, then 120 mm of vanes atop. It's a simple design, low cost, and highly effective for moderate to high loads. I used this on an AMD Phenom II X4 955 Black Edition and an AMD Athlon X2 5200+ and it performed perfectly acceptably. Bit-Tech's results for this cooler show a good example of a trap reviewers can fall into. The Freedom Tower is within error of the much, much, much more effective Cooler Master V8. Why would this be? Why would a quite basic tower cooler perform up there with an eight heatpipe, four fin-stack monster? There isn't enough thermal load. A big tower cooler's heatpipes are as effective as each other at low thermal loading, but the bigger and better cooler will be able to maintain a lower temperature as the heat energy rate (the wattage) rises. If the heat loading isn't high enough, the biggest heatpipe cooler possible won't perform any better than a smaller unit: Heatpipes work on evaporation, which resists a rise in temperature, until the heatpipe is saturated. As all big tower coolers are heatpipe limited, we need a much higher thermal load to allow the big boys to strut their stuff. They used real CPUs, a Phenom II X4 at 3.6 GHz and a Core i7 965 at 3.6 GHz. Neither of those would go much beyond 125 watts in Prime95. To properly allow something the size of a Cooler Master V8 to show us how much capacity it has, we need to be hitting 200 watts. It's somewhat like filling two buckets of similar width and reporting on the water level. If we never actually fill the buckets to their capacity, we're not really measuring the capacity of the bucket. To properly compare coolers, a known thermal load is needed, either from a heater plate or from a modern CPU which can report its power usage. This allows us to not only compare a known loading, but to raise that loading for larger coolers. Back to the Freedom Tower. Like all 120 mm four heatpipe designs, it ran well with a 75-100 watt load. Above that, it started getting to the 65-70C above ambient domain. This was back when I still had a resistive heater block so could test known powers. At 150 watts, it ran at 80C above ambient, and logged a 100C temperature on the hotplate. This was about normal for the design of the heatsink, and I wouldn't doubt a modern 4 pipe 120mm tower (e.g. Hyper 212) would score about the same. Type: Four heatpipe tower Fan size: 120 mm Power rating: 125-150 watts

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Fans, Static Pressure and Airflow |

In the 2000s and up to around 2015, manufacturers were touting two types of fan, "airflow" and "pressure" fans. Airflow fans had high cubic feet per minute (CFM) ratings, but low static pressure ratings. Pressure fans were the opposite. We'll cover them in that order, and examine why they're now obsolete. An airflow fan (or a η fan) was usually low RPM with many thin blades. They were optimised not for airflow (any fan does airflow!) but for noise. An airflow fan would run at 1,200 to 1,800 RPM, quietly. Any faster than that and air disturbed by one blade would not be cleared when the next blade came, so caused turbulence, instability, and vibration. So an "airflow" fan was really just a fan meant to be quiet, which meant efficiency: Thin, widely spaced, and many blades did this. Most fans of all sorts are recurved, the blade is curved forwards like a scythe, an airflow fan usually has a much greater recurve than a pressure fan, since the recurve aids in efficiency. Pressure fans (or Ψ fans) have fewer blades, and the blades they do have are usually running at a higher angle of attack. Their blades have a much lower aspect ratio (they're wider relative to their length) and the fans usually run faster, 1,800 to, well, in some cases over 7,000 RPM. They eschew noise levels for pure output and can push air with greater force (so higher pressure) than other fans. This they do with their lower aspect ratio and higher RPMs. Pressure fans are, therefore, usually quite noisy. At the high RPMs, an airflow fan actually pushes less air than a static pressure fan does, but does so with much less noise. At low RPMs, a pressure fan falls off badly. As for the symbols, "Ψ" is the static pressure coefficient and "η" is the efficiency. Why, then, did we need two designs? Static pressure falls off as airflow increases, as static pressure (in pascal or mm of water) is a measure of impedance. The more airflow a fan pushes, the less static pressure it is able to overcome. This makes sense if we consider an air filter, an example of a very high static pressure system. We can't push a lot of air through it, meaning pressure builds up between the fan and the filter. If we had a stronger fan, it would push more airflow, but also cause a much higher pressure in order to do so. This same principle applies to any obstruction airflow, such as a heatsink or a radiator. Therefore we used fans optimised for high static pressure to force air through the dense vanes of a heatsink (or a case air filter) but low static pressure fans for the higher airflow needed to get air into and out of a PC case. Ideally we'd use Ψ-fans on our coolers and intakes (to pull air through dust filters) and unobstructed η-fans on our exhausts. This also comes to a further conclusion: In a push-pull configuration, the only purpose of the "pull" fan is to reduce the impedance facing the push fan, so the push fan does not need to develop much static pressure and can push more airflow. Two airflow fans in a push-pull setup on a tower cooler could outperform a single static pressure fan at a lower noise level. Of course, if the user just used two static pressure fans, he saw no benefit. In this configuration, with two airflow fans, the highest output fan should go on the pull side to cause slight negative pressure ahead of the pushing fan. So why don't we bother with the distinction today? Why's one design enough? We worked out how to get the best of both worlds. Using a very strongly recurved blade, we can have blades at a very high angle of attack, similar to a pressure fan, but at a higher aspect ratio, similar to an airflow fan. This "flattens the curve", so pressure doesn't rise and fall so fast with airflow. These fans work well across very wide RPM ranges, can build a good static pressure and push a lot of air when there's little impedance, so have a high free space CFM rating. "Static pressure" vs. "Airflow" is now mostly meaningless. Noctua will sell you, with a straight face, a nine-bladed "static pressure" fan with very strongly recurved blades. It is, of course, a modern all-purpose fan, but people haven't caught up with the times yet. If you're reusing older fans, then: Wide, less curved, fewer blades: Static pressure optimised Thin, curved, many blades: Airflow optimised If we're doing push pull, then airflow on the out, static pressure on the in. Same applies to case cooling. This brings us on top why all fans have an odd number of blades. It's the same principle as why gears tend to go toward prime numbers of teeth (and never do 1:1 ratios, a 1:1 is done by something like 7t-13t-7t), it avoids resonant coupling. A very slight imbalance to the fan can only ever cause one deviation per rotation. With an even number of blades, the opposite blade is then automatically also not balanced, which then also causes a motion around blades at 90 degrees: We get a lot of vibration. Veterans will recall the Yen-Sun Technology Corporation (YS Tech), formerly a top-tier fan manufacturer, along with Nidec and Delta. In the early 2000s, YS Tech invented the tip-magnetic-drive fan, which turned the brushless motor inside out, placing permanent magnets on the tips of the fan blades and electromagnets in each of the four corners of the square chassis. This allowed simpler coil windings, a smaller hub dead spot, and very easy assembly. The slight coil whine as they started up made a relatively pleasing sci-fi style sound as the fans spooled up, before fading as the torque was no longer needed. They were also quieter than other fans of the same output. With all these advantages, why didn't they take over the world? The Wikipedia article is an unsourced stub which manages to cram in five facts, one of them wrong, without any sourcing. The original fans had a problem with the metal case, used for magnetic shielding, causing the fan to lose speed regulation if the casing was grounded, probably due to a bad connection inside the case: The coils were soldered together quite sloppily, so exposed joints could easily touch the inside of the fan's outer case. Given that they would normally be making electrical contact to the heatsink, which would often be grounded through the motherboard, this would become a major issue: The fan would underspeed, overspeed, fluctuate in speeds, and even destroy itself! They became known for failing early. Swiftech used them on the highly regarded (and bizarre, I'd be interested in collecting one) MCX4000, which was a copper baseplate with literal screw threads bored into it as surface area! |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| TBC |

Corsair H80 CLC CLCs came of age with the advent of very small high pressure pumps and the use of propylene glycol as a coolant. The key enabling technology was the development of a very low fin pitch skiving process at Asetek. Fins became from mm per fin to fins per mm, allowing low cost impellers to circulate coolant cost-effectively, and making traditional "maze" style watercooling blocks (e.g. from the likes of Danger Den) obsolete overnight. Very quickly models from Fractal Design, Corsair, NZXT, Swiftech, etc. all appeared at very attractive price points. Even AMD got in on the action and began fitting them from the factory to some high end GPUs. Mostly, they were identical and differed in the fans supplied, because they were being made by the same supplier: Asetek. Cooler Master, Apaltek and some others got in on it, but even they largely used the same radiators. The advantage of a CLC, indeed any liquid cooler, is that the heatsink or radiator device can be placed out of the way, it's not limited by whatever will fit mounted to the motherboard. This means it can be very big, very heavy and very dense, all highly desirable traits for a heatsink. Corsair's H80 runs three profiles, cycleable via a button on the CPU plate, predictably "low", "medium" and "high". The pump, in my case, is silent, but others have reported noise. The fans do not spin down much at all when on medium and high, and always make noise. On high, quite a lot of it, so those who can thermally control their fans are advised to put the pump on full and control the fans themselves. It is immensely effective. It sustained a full load highly overclocked Phenom II X4 955 BE at 3.8 GHz, at below 70C. (On the Phenom II this is a calibrated "Tjunction", intended to take the integrated heatspreader into account, actual die temperature would have been in the 90s) Of course, an overclocked Phenom II won't last anyone forever, and it was replaced by a Core i5 2500. The H80 was set on "low", and controlled the fans itself. Under full load from Prime95 small-FFTs, the Sandy Bridge reported itself as using 76 watts total. This is hardly going to strain anything, so OCCT was brought in. The TDP's 95 watts, let's try to get closer to it? OCCT managed 62 watts and the CPU didn't even break 60C. This became a challenge! Manually limiting OCCT to 4 threads and a small data set got package power up to 76 watts and temperature to 65C, but surely we can do better? OCCT's AVX capable Linpack came next. AVX is responsible for a lot of power, and we hit 80 watts quite quickly while temperatures stabilised at 70C. I can only assume the thermal interface is rubbish or the H80 needs more pump speed - so it was set to "Medium" while the test was still running. Fans ramped up, pump RPMs (reported via a 3 pin fan connector, a neat touch) ramped up, noise ramped up and... Nothing. Temperature remained flat at 70C, a few flicks to 71C, then power dropped to 48 watts before resuming at 80 watts, ruining the nice flat temperature trace. The temperature made no further threats to reach 70C. Clearly something more reliable a load than OCCT was needed. IntelBurnTest got to 78 watts but was all over the map. 7Zip's benchmark got to 46 watts and was a bit of a joke, but it's mostly memory bound anyway, and actually scored worse than the peak result I'd seen on the Phenom II X4. Tweaking it to fit the dictionary in L3 cache and running a few more threads helped close in on 50 watts, but this isn't a stress test for thermals. An old favourite was "burnk7", hard to find, and designed to present maximum load to an Athlon back in the day. It was also a very high load for Core and Core 2 processors, but evidently not for Sandy Bridge: Which hit 51 watts only. I then updated Prime96 from 27.9 to 29.4, which is AVX aware. CPU hit 75 watts immediately but went little further, stabilising around 76.5W. I left this going at 64C and ramped the H80 up to "High". Temperature fell slowly to 62C and stayed there. With a resounding "Meh" from this whole round of testing, I set the CLC back to its "Low" profile. Temps very slowly rose back up to around 66C. The only conclusion is that a low 70-80 watt load just isn't enough to let the Corsair H80 strut its stuff properly and it is more suited for a higher loading. The cooler died while in service of an i5-3570K, the impeller stalled, slowed, struggled, and the CPU rapidly overheats. I tried to empty and refill it with monopropylene glycol, but it did seem the impeller's bearings were shot. This is a common failure mode of AIOs, the impeller is basically the driving circuitry, bearings, etc. of a fan, with an impeller chamber instead of fan blades. However, pumping liquid is much more hard work than blowing air around, so the power needed is much higher, resulting in a shorter lifespan. Type: Closed loop liquid cooler Fan size: 120 mm Power rating: 75-110 watts

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The Closed Loop Cooler or The All-In-One Watercooler |

In the early 2010s, Asetek developed a very fine copper skiving process able to produce dozens of fins per centimetre. With a suitably low viscosity coolant fluid and a channel pathway to run through the fins, this made a cheap, and excellent, waterblock. Asetek paired this with an impeller design as a pump, which ran smoothly and quietly (in most cases!) and a suitable coolant, usually propylene glycol. Water isn't suitable for this kind of sealed operation, it tends to allow crap to grow in it, it corrodes copper, it dissolves oxygen and needs regular maintenance. It also has a high vapour pressure when running at hot temperatures, a water cooling loop over around 70C will have enough pressure as to blow out gaskets, so water cooling loops for higher power use tend not to be closed loop, they run at atmospheric pressure. This isn't suitable at all for a "install and forget" consumer product. In designing this, Asetek got the price down so as to be able to compete with high end aircoolers and, for the most part, made them obsolete. A radiator could be mounted directly to the case, such as Corsair's (Asetek manufactured) H80 featured here. This allowed a radiator to be bigger, heavier, and denser. For the same size, a radiator was always going to win: Cooling is a surface area race and always will be. It also encouraged (even enabled) better case airflow design by novices. It was obvious that the radiator should be an exhaust so, at high CPU loads, the case got better airflow. Most case cooling setups focus on getting cool air in, but don't deal sufficiently with getting hot air out. A CLC or AIO deals with this problem elegantly. A good airflow setup does not always have the radiator as an exhaust. If a very high power CPU is used, the radiator can be best used as an intake. The radiator then gets fresh air directly, without any other component (typically the GPU) pre-heating it. The somewhat embarrassing inefficiency of Intel's Raptor Lake in 2022-2024 favoured this sort of layout. Good cooler design always makes the surface area of the actual dissipation surface the limiting factor, so high flow rates of coolant are needed. Asetek's 800-2,400 RPM impellers handled this well. So, how well did they perform? Just like tower coolers of the same surface area! A common 120 mm slimline CLC (like the Corsair H60) was at entry level tower cooler standard, so maybe as good as a Cooler Master Hyper 212. The more common not-slimline 120 mm radiators initially used very dense fins and a large depth, but this was expensive, so they became smaller by around 2016-2018, and at that point a good tower cooler would beat them. Larger 240mm or even 360 mm double-wide or triple-wide coolers ran with the very best aircoolers. A solid and not silly-thin 360 mm AIO could beat more or less anything. Ultimately, they have to get heat into the air, like any other cooler does. It's a surface area race and always has been. If heat starts backing up in heatpipes or coolant fluid, any cooler will fail to keep the load below a threshold temperature. In the 2023 and onward timeframe, "slimline" AIOs began appearing. These, of course, did not perform well. Cooling is a surface area race and a smaller radiator is a worse one. At about the same time, twin-stack aircoolers appeared, offering enormous surface areas and usually sporting six to nine heatpipes: Heatpipes are many orders of magnitude more effective at moving heat than any coolant fluid is. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Nova RGB These things appear everywhere under many names. On AliExpress, they're branded "GreatWall", for example. I've also seen Juno Pro, Nova RGB, and many more names. They're either clones of the Thermaltake UX100 (not a referral link) or the UX100 is just Thermaltake's branding for its version from the same factories. Thermaltake's version has a honeycomb-like aluminium structure to increase surface area, and doesn't use really tiny thin fins. It is also awful. How much worse can we make the UX100 by just not even trying to make a cooler? They all come with push pins to attach a round plastic bracket, which the retention clip attaches to. A simple, and effective, way to give wide compatibility. It will clip directly to AM2/3/4 and the bracket gives it wide Intel compatibility for any 75-80 mm spacing: It doesn't work on LGA2011 of any version, but can be more or less adapted to it. I initially ran it on a Xeon E5-2640, a TDP Intel rates to 95 watts. This was unfair, as the cooler was never intended for LGA2011 and Thermaltake's version is rated to 65 watts only. I didn't have a real LGA2011 cooler at the time. Of course the CPU hit thermal limits. So, if 65 watts was the rating, I tried the rating: A Ryzen 5 5600X, which is rated for 65 watts and even comes with a very basic Wraith Stealth cooler, a radial fin aluminium thing from Cooler Master which is entirely "basic". The Nova RGB dramatically underperformed the Wraith Stealth while being a lot larger (75mm above the base, the Wraith is 60 mm). With default settings, so Precision Boost Overdrive 2 (PBO2) disabled and only Core Performance Boost enabled (as this is AMD's spec), Cinebench R20 caused the Nova RGB to hit the 95C throttling point of the Ryzen 5 5600X. The Wraith Stealth hit the high eighties, and would only reach throttling temperature with PBO2 enabled. You read that right. This is worse than a stock 65 watt cooler. In fact, it is the worst 120mm cooler I've ever tested. This is down to mostly one thing: It is extremely lightweight. A recent update to the line (e.g. Mars Gaming MCPU120 RGB) has slightly redesigned the vane profile, which won't change performance. A heatsink works by sinking the heat into a thermal mass, which offers resistance to temperature rises. Then, in most cases, forced convection is used to run lots of cooler air across that thermal mass, taking the heat energy away. See the second photo on this entry? The entire thing is hollow! It doesn't have remotely enough metal (it's aluminium with some steel screws) to do that job well. Aluminium is also a quite poor thermal conductor, so the edges of the many vanes don't get warm enough to contribute to cooling, this being wasted area, and area is very important for a heatsink. The four posts holding up the fan are actually the most effective part of the heatsink, but have no vanes and little surface area. I reckon this would be improved a fair bit by adding small RAM heatsinks to them! Be very wary of low profile coolers with the fan embedded into them. That means the cooler has no room for more metal near the CPU, where it is useful. A single heatpipe, or even a copper inlay, would have improved the performance here dramatically. However, as it is, I could not recommend this for any load higher than 50 watts. It simply won't handle it and you'll end up with throttling. If you want to bling out a Pentium or Core i3, maybe a Ryzen 3, anything around 20-45 watts, it'll be acceptable... But just be aware of how much performance you could have had for the same price: A Cooler Master Hyper H412R/411R or TX3 EVO would wipe the floor with it. For low profile cooling, Arctic's Alpine 12 CO is half the price of an already budget cooler, and runs substantially better. No, really, this is so lightweight that the most basic cooler will beat it. Are there, then, any positives? Some, but minor. There's a lot of wash going to things like RAM and VRMs, but if they're getting hot then you probably have far more load than this heatsink is able to handle. It's low profile and lightweight, which can help in some builds but, again, better is available at a similar or lower price. Avoid. Type: Pressed radial aluminium stack Fan size: 120 mm Power rating: 40-50 watts

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

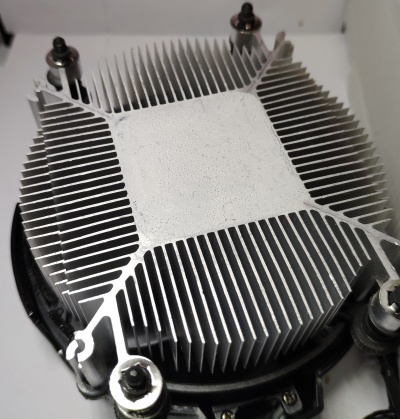

Cooler Master Hyper 212 Black Edition Cooler Master's Hyper series have a long and quite good history of being price-effective coolers. You get heatpipes directly contacting the CPU heatspreader (so contact isn't all it could be, but the heatpipes do get best exposure) and a big stack of aluminium vanes. With this one, Cooler Master supplied a "Silencio" fan, a low RPM, low output 120 mm fan, but also supplied clips (annoying clips!) to fit a second fan. Push-Pull configuration with two much more powerful fans didn't achieve anything over a single more powerful fan. If you want to tune for noise, have the "pull" fan running lower than the "push" fan, it will reduce impedance and give the same airflow at a lower noise level. The Hyper 212 Black Edition began life, believe it or not, in 2007 with the launch of the Hyper 212. The point of this was to make a large and very cheaply made tower cooler with whatever fan was cheapest that year, Cooler Master often just changed the fan without notice. It was the go-to CPU cooler for over ten years, finally falling out of favour in around 2017-2020 as a new generation of aircoolers emerged. The one constant thing was the fan mounting clips. They were awful. The indent in the finstack was just not deep enough for a secure mounting. A Hyper 212 was always, always, difficult to mount. It uses captive-spring loaded bolts to attach to the retention mechanism which require a lot of downforce, over your motherboard, so one slip could be extremely expensive. The mounting is also poor at distributing pressure. That said, however, from 2010 to 2020, if you asked for a cost-effective mid-range cooler for a thermal load below 100 watts, everyone, everywhere, would tell you to get a Hyper 212. Cooler Master must have sold millions of them. They're still utterly everywhere in e-waste recycling, where I saw a bench of eight of them for £5 each (3 for £10!). The fan's a five bladed design with big, swept, broad blades. These are suitable for both good airflow and good static pressure, the days of an "airflow" and a "pressure" fan being distinct are long behind us. Keeping costs down, the heatpipes are double-ended, so the hot end is actually in the middle of the heatpipe and each end is a cold end. This does hurt efficiency a little, but four long heatpipes are a lot cheaper than eight shorter ones and almost as efficient. Cooler Master seems to have been first to do this, and does it across many product ranges, notably in the Hyper 212, but also in the MasterAir series of higher performance units (e.g. MasterAir MA410) A double ended heatpipe will saturate at a lower thermal loading than two independent heatpipes of the same combined length. In testing, I removed the fan and replaced it with a higher output model. The load was a calibrated Ryzen 5 5600X to 100 watts PPT running Prime95, monitoring it to ensure it remained at 100 watts. Temperature was 74C above ambient, which ties in with the results others have seen with this cooler. For a 100 watt load into a £35 heatsink, there are no complaints at all. For the Ryzen 5 5600X, this cooler allowed Precision Boost Overdrive 2 to extract 95-99% of its absolute maximum. In non-pathological workloads (e.g. X265, OCCT, CinebenchR23) it kept the CPU below 85C for an all-core boost of around 4.45 GHz. Even pathological cases like the Ryzen Master stability test, or Prime95, would only barely scrape the 95C thermal limit of the CPU. Compared to even modern coolers for a 60-70 watt load, the Hyper 212 Black Edition still sits with the pack without any major redesign since 2007. It sits right next to the Arctic Frezer 34 Esports Duo, a significantly more expensive (and louder) dual-fan cooler, and beats Cooler Master's own MasterLiquid ML120L all-in-one liquid cooler. 120 mm liquid coolers are, for the most part, junk: They plain lack the surface area. Stylish, big, and good for loads less than 90 watts. Common 65-75 watt desktop CPUs were the Hyper 212 series' bread and butter. It has been used on 120 watt CPUs, but you're looking at 75C+ over ambient. To be fair, Cooler Master doesn't rate the Hyper 212 for this kind of load. If you want to use a Hyper 212 with this kind of load, use a more powerful fan. Older Hyper 212s often used really bad fans, so a quick fan change could be all an older Hyper 212 needs to get up to date. All variants of the Hyper 212 are the same design and same baseline performance. Cooler Master gives different fans on some, two fans on some, decals and etching on some, but they're the same dimensions, same heatpipes, same construction. By early 2023, the Hyper 212 was going out of stock in some places, and it seemed Cooler Master was working on something newer. It was right at the edge of what it was capable of with a 100-110 watt load and, while it would handle above that, maximum achievable boost clocks would be limited. A very large CPU die (e.g. Xeons) would be able to dump more power into the cooler, of course. Type: Four heatpipe tower Fan size: 120 mm Power rating: 100-110 watts

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The Tower Cooler | Since inception in the mid-2000s, the tower cooler has been where performance is. How, then, do we spot a good one among the hundreds out there? First, we ignore the fan and focus on the heatpipes. Most tower coolers show quite lazy performance curves as fan airflow goes up and replacement fans are plentiful. We look at only a few factors, the first, and most important, is the number of complete heatpipes. A mid-heat design, with the heatpipe being heated from the middle and both ends going into the fin stack is worth about 1.8 heatpipes. They are more efficient than just one heatpipe, but not as efficient as two full heatpipes. Four heatpipes is the minimum for acceptable performance on high (75 watt or more) heat loads. Ideally, you'll have six or more. If we reach eight, physically fitting those in usually requires dual fin stacks. These are always extremely serious coolers and very efficient. Second, size. More fins/vanes is more better! Really, as always, nothing substitutes for surface area. The aim of a heatsink is to get heat into the air, which can only happen at a surface. If it's small or low profile or slim, it's not going to be high performance. If it's a huge six-heatpipe behemoth with two fin stacks then, no matter how else it's designed, it's probably going to be a very effective cooler. A small heatsink with six heatpipes (e.g. those many 92mm fan ones from China) is not going to perform as well as a four heatpipe design sized for 120 mm fans: The 120 mm unit is just bigger, has more fins, and more surface area. Size matters. However, most tower coolers are not limited by surface area, but instead by their heatpipes. Similarly, most AIOs are limited by their liquid flow rate: Lots of surface area is easy, getting the heat to it is the problem. Lastly, we look at the fin or vane design. Those with air guides (or shrouds) along the sides generally do a better job, if slightly. They will work better with lower flow fans. The Hyper 6+ on this page is shrouded, but the Hyper 212 is not. The Hyper 6+ was marketed as a performance heatsink, not a mid-range/mainstream one! These help in some cases (and inside some cases) but usually a tower heatsink isn't limited by airflow. Only very small tower coolers can become airflow limited, the larger ones are limited instead by the efficacy of their heatpipes. A 75 watt load on the Hyper 212 here gets it to 60-65C above ambient, regardless of how much airflow is thrown at it. With a 7.2 watt static pressure fan (which is a lot of fan!), it showed the same performance at 1,500 RPM as it did at 3,100 RPM, and this holds true for nearly all tower coolers. Once the heatpipes and vanes are at their limit, adding airflow won't help. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

AMD/Cooler Master Wraith Stealth Everything a basic cooler should be and nothing it shouldn't. There's a big chunk of aluminium going all the way up the cooler with radial fins around it. This gives both a big thermal mass and a large surface area in the minimum volume. AMD's Wraith Stealth is a variant on Cooler Master's "Standard Cooler" line (basically a Standard Cooler I50 with a different fan and mounting), completely no-nonsense, get the job done heatsinks. It's rated to 65 watts, has no copper inlay, is just 60 mm high with the fan included, (46 mm without) and isn't here to look flashy or to win prizes. It's there to keep a 65 watt AMD Ryzen within its performance targets. The fan goes to around 2,700 RPM, isn't too noisy and, in testing with a Ryzen 5 5600X, kept the CPU below 90C under normal, non-overclocked operation. It doesn't offer a lot of thermal headroom for Precision Boost Overdrive 2, but it's also not intended to. PBO2's defaults can raise power up to around 105 watts in some cases, which is not what this cooler is rated for. This then puts the CPU to its thermal limit (95C by default) but also extracts a small boost in performance. Of course a better cooler will get more performance out of PBO2 than the Wraith Stealth can. This is the point: You're getting the performance you paid for and AMD includes a cooler which will get you there. If you want more, that's there too, but you'll need better thermals. The performance difference isn't great, but it is essentially included with any better cooler: Cinebench R20, Ryzen 5 5600X, Wraith Stealth: 4148 Cinebench R20, Ryzen 5 5600X, CM Hyper212 Black: 4470 That's ten percent uplift from turning on PBO2, which is technically overclocking. If you don't ever intend to overclock, then the Wraith Stealth gets you everything you need in a small form factor and has plenty of wash for VRM cooling. While AMD says this is a 65 watt cooler, it will reach thermal limits at that kind of power, so is best used on CPUs which will not exceed 50 watts. Type: Extruded aluminium core with radial fins Fan size: 120 mm Power rating: 45-60 watts

|

|

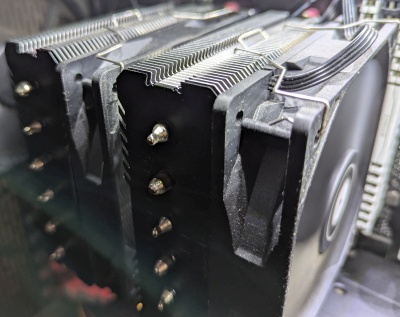

Thermalright Peerless Assassin 120SE In 2024, £37 got you this. You read that right, this is a budget cooler. On release in 2023, most reviewers were actually shocked. Not only did Thermalright invite comparisons to 240 mm AIO liquid coolers, the Peerless Assassin smoked them. The "SE" version lacked the end plates covering the tops of the two finstacks, but otherwise was identical. Performance could have been improved by closing off the sides and maybe ducting the entire thing, or "pulling a Noctua" and using giant fans with it, but none of that would work for a £35 aircooler. Neither did it need to. The Peerless Assassin 120SE took Noctua's painfully expensive NH-D15 (£115!) and beat it. Not by a little bit either. In noise-normalised testing, it beat the NH-D15 by three and half degrees. How does it manage this when it has only two quite thin finstacks? Well, a finstack doesn't need to extend far from the heatpipe, as aluminium is not good at conducting heat. This is why we use "U" shaped heatpipes, it puts the thermal loading into more metal and, importantly, gets more of that metal closer to the heatpipe. Where Thermalright could cut corners, such as the fans (they're not great), it did cut corners. £35 will do that. However, the core cooler is a fully effective 120 mm dual-stack and performs exactly as one would expect it to. Gamers Nexus absolutely loved it, and Steve's not known for holding back if something disappoints him. In his testing, it sat right next to a Lian Li Galahad 240 AIO. Thermalright has a Phantom Spirit of the same design, but seven heatpipes and it's even more effective My real CPU testing was a Ryzen 5 5600X at all-core 4.45 GHz and a PPT (package power tracking) of 106.5 watts in Prime95 (FMA3). Temperature settled at 87-88C for the single CCD, with individual core temperatures ranging from 76.1C to 90.2C. Cores 0 and 2 ran particularly cool, while Core 1 didn't pass 84.2C and that core was the one limiting the maximum achievable clock! Cores 3, 4, and 5 all went above 88C. Core 4 consistently ran the hottest. You may ask why the temperatures are so high on a 106 watt loading? The Vermeer CCD in the Ryzen is a tiny die, just 83.7mm². The power density in there is absolutely enormous, 1.27 watts per mm²! Getting all this power out of the die, through the IHS, to the cooler is not an easy task. The IHS doesn't hold much of it, as the I/O die was reporting a nice comfortable hotspot temperature of 47C maximum. No matter how hard I tried (and I tried hard), I could not get more than 110 watts (measured via PPT) out of the Ryzen 5 5600X! One last note on dual-fan coolers (push-pull), offset the pulling fan (the one in the flow of the pushing one) to be a bit lower than the pushing one (or offset the puller to be a bit higher). This helps with impedance matching, we discussed this a little above when talking about fan design, meaning that two fans can run at lower RPMs than a single fan, and move the same amount of air. This is usually always quieter. Type: Six heatpipe twin-stack tower Fan size: 120 mm Power rating: 200 watts

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Why does the same cooler do better on some CPUs than others, even if the CPUs are the same power? This question comes up a lot, and it's well worth considering. The 135 watts of a Xeon E5-2690V4 is quite readily cooled by a Cooler Master Hyper 212 Black Edition, but the 100-110 watts of a PBO-overclocked Ryzen 5 5600X is quite poorly cooled by it, reaching 85-90C. What gives? Similarly, Athlon "Palomino" had a reputation for running hot while a Pentium 4 Willamette didn't, even though the Willamette actually made more heat. Intel's Prescott ran hot as hell, but its competing Clawhammer from AMD used similar power and ran much cooler. How does this backwards logic work? A big part of how easily a CPU (or GPU, or anything else for that matter) can be cooled is thermal density. If there is a lot of heat in a very small space, it is very difficult to spread that heat out so it can reach all parts of the cooler. Direct die contact is the best way, but only with a good cooler. Both major CPU manufacturers include an "integrated heatspreader" (IHS) on the package, which is usually nickel plated copper and soldered to the CPU die, though Intel often uses a pretty bad thermal compound instead. This is meant to counteract this effect for aluminium based coolers, but actually gets in the way for coolers with copper bases or heatpipes. In any case, how easily it is for a silicon die to lose heat (so, to be cooled) is related to how much heat is coming from how much area, a thermal density, which we will measure in watts per square millimetre, W/mm². Let's take a look at some of them. We'll avoid de-clocked parts, which would skew the data, and go with high end products intended to be pushing the limits. We'll also use maximum typical power (e.g. PL2 on Intel or PPT on AMD), not "thermal design power", where the latter is not reflective of actual heat loading.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||